Tesla Co-Founder Joins With Toyota to Recycle Car Batteries

(Bloomberg) -- Toyota Motor Corp. is tying up with Redwood Materials Inc., a battery recycling company created by Tesla Inc. co-founder J.B. Straubel, to collect and repurpose cells from some of the earliest battery-powered vehicles.

The world’s biggest automaker and Redwood plan to create a “closed-loop” supply chain for electric-vehicle batteries that involves collecting end-of-life cells for reuse and repurposing of materials, according to a statement Tuesday.

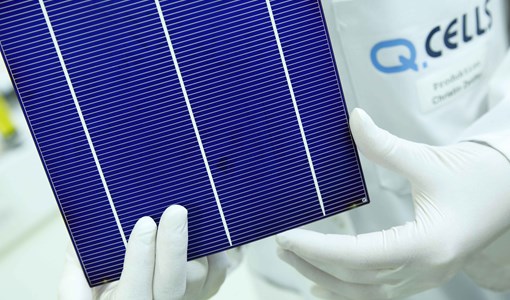

The companies will initially try testing and recycling batteries from Toyota’s early-generation Prius models, the world’s first mass-produced hybrid car when it made its debut in the US around the turn of the century. Battery-powered vehicles retiring from roads today are “predominantly” Priuses, according to the statement.

Toyota and Redwood plan to address surging battery prices and shortages of metals and materials that are forecast to accompany a rapid global shift to EVs. Battery supply snags alarming the auto industry aren’t likely to go away anytime soon, Toyota’s Chief Scientist Gill Pratt warned in a recent interview. With costs already high, climbing battery prices could weigh on EV adoption, according to Pratt.

“We’re going to be in a pretty chaotic period through the entire ramp up and transition of the fleet to electric, that’s when we need the most materials -- from recycling, mining, all sources,” Straubel said in an interview. “It’s going to be a few decades” before shortages ease and carmakers can rely mostly on recycled materials.

Redwood, the biggest lithium-ion battery recycling company in the US, aims to bring down battery costs by mass supplying materials derived from recycled cells. It aims to produce enough anode and cathode components for more than 1 million EVs a year by 2025.

The companies’ operations will initially mostly take place at a Redwood facility in Nevada. Redwood said it is planning to build another so-called battery materials campus near Toyota’s first US battery plant in North Carolina.

(Updates with Redwood CEO comment in fifth paragraph)

More stories like this are available on bloomberg.com

©2022 Bloomberg L.P.

KEEPING THE ENERGY INDUSTRY CONNECTED

Subscribe to our newsletter and get the best of Energy Connects directly to your inbox each week.

By subscribing, you agree to the processing of your personal data by dmg events as described in the Privacy Policy.

More renewables news

SunPower Slides After Disclosing Plans to Restate Earnings

Apr 23, 2024

AFC Joins $20 Billion Morocco-to-UK Subsea Power Export Project

Apr 22, 2024

China’s Rapid Solar Growth Slows as Grid Seeks to Keep Pace

Apr 22, 2024

Europe Is Being Scorched and Flooded by Growing Climate Extremes

Apr 22, 2024

Biden Unveils Winners of $2 Billion in Green Tax Credits

Apr 19, 2024

Europe’s Demand for LNG Set to Peak in 2024 as Crisis Fades

Apr 19, 2024

Clean Hydrogen’s Best Bet May Be a Rainforest State in Borneo

Apr 18, 2024

PG&E, Edison, California Apply for $2 Billion US Grid Grant

Apr 18, 2024

China’s Solar Surge Is Making a Missing Power Data Problem Worse

Apr 18, 2024

First Solar Jumps After Report Says Biden to End Trade Loophole

Apr 17, 2024

Chevron helping drive Egypt’s journey to become Africa’s energy powerhouse

Mar 11, 2024

Energy Workforce helps bridge the gender gap in the industry

Mar 08, 2024

EGYPES Climatech champion on a mission to combat climate change

Mar 04, 2024

Fertiglobe’s sustainability journey

Feb 29, 2024

P&O Maritime Logistics pushing for greater decarbonisation

Feb 27, 2024

India’s energy sector presents lucrative opportunities for global companies

Jan 31, 2024

Oil India charts the course to ambitious energy growth

Jan 25, 2024

Maritime sector is stepping up to the challenges of decarbonisation

Jan 08, 2024

COP28: turning transition challenges into clean energy opportunities

Dec 08, 2023

Why 2030 is a pivotal year in the race to net zero

Oct 26, 2023Partner content

Ebara Elliott Energy offers a range of products for a sustainable energy economy

Essar outlines how its CBM contribution is bolstering for India’s energy landscape

Positioning petrochemicals market in the emerging circular economy

Navigating markets and creating significant regional opportunities with Spectrum