Building resilience: Why now is the time to invest in natural hazard risk management

From raging wildfires in Australia at the start of 2020 to the devastating flash flooding across much of Europe in July 2021, recent years have been scattered with natural hazard events that have destroyed property and infrastructure, devastated businesses and taken lives.

In the US, Hurricane Ida brought back painful memories to the people of New Orleans, a city which is still rebuilding after Hurricane Katrina caused 1,800 deaths and $125 billion of damage back in 2005.

Unfortunately, natural disaster events such as hurricanes, cyclones, storms, floods and wildfires are occurring more often and with greater severity. This can be viewed in terms of economic cost increasing over time.

The Asia Pacific region tells a similar story. Here, average annual disaster event-induced economic losses between 2000 and 2009 stood at $56.7 billion – and for 2010-2019, that figure more than doubled to $117.9 billion. The Tohoku Earthquake which struck Japan in 2011 is largely responsible for this, but even when removing 2011 from the period, the nine remaining years average out at $89.1 billion in annual natural disaster damage.

In the US, meanwhile, the ten-year average annual cost of natural disaster events exceeding $1 billion increased more than fourfold between the 1980’s ($18.4 billion) and the 2010’s ($84.5 billion) Source: NOAA National Centers for Environmental Information (NCEI) U.S. Billion-Dollar Weather and Climate Disasters, 2021.

Such has been the impact of growing and more severe weather events, the magnitude of the 100-year and 500-year flood has undergone revision in Houston, a significant development that experts are keeping a close eye on.

Counting the cost

These concerning figures translate into a multitude of damages encountered by organizations that operate across a variety of industries, which notably include petrochemical, energy, chemicals, technology and other industrial sectors with large and highly valuable infrastructure bases.

Unplanned outages and economic losses from production downtime are major consequences of the disruption caused by extreme weather events.

Beyond this, there are many secondary and tertiary social and environmental impacts that stem from the primary damage done to these businesses.

But why are power and chemical plants particularly prone to natural disaster events?

Geography plays a critical role here. For instance, many petrochemical facilities are strategically located close to coastal and inland waterways to enable easy transportation of goods in and out of their sites.

However, this makes them especially susceptible to hurricane and flood risks. In the US, many plants and industrial sites are located near the Gulf Coast, Atlantic Coast and Mississippi River. Earthquakes are another risk factor, primarily in the western states and other regions near fault lines. Key risk areas in Europe include sites along rivers and coasts, including those in regions which are at or only slightly above sea level.

As we head towards COP26, there is a greater sense of urgency among key political decision-makers, enterprises and wider society.

Hosted in Glasgow, UK, the summit represents a defining moment for Britain’s Prime Minister Boris Johnson, whose government is pushing ahead with some of the most ambitious climate targets a UK government has ever pledged.

But enterprises should not wait for more comprehensive legislation and regulation to prompt them into action.

In many regions around the world, there are little or no regulatory drivers aimed at industrial facilities that require them to withstand extreme weather events. The onus currently is on organizations to determine any natural hazard risk management strategy, and given the growing frequency of these incidents, the time to act is now.

How to approach natural hazard risk management

The extent and nature of such action is largely dependent on each individual business’s appetite for risk – in other words, the extent to which your business is prepared to deal with disruptions caused by storms, hurricanes, wildfires, floods and other extreme events.

Direct concerns may include the reliability and resilience of your organization’s equipment, facilities to provide worker safety and reduced unplanned outages.

However, it is also important to bear in mind that physical damage to buildings and equipment represents only the initial source of financial loss.

Resulting business disruption and market displacement can also hit revenue figures hard, depending on the severity of the natural hazard in question. Concerns here can center around storing materials and disruption to feedstock supply, transportation availability and access, and cost and availability of energy.

To help quantify some of these risks, organizations should consider a range of factors.

What amount of revenue will be lost if I have to shut down my facility for an extended period of time? Can additional understanding of the risks help my company to manage our operations? Will improvements to preparedness and response reduce direct damage and limit revenue loss following an extreme weather event?

Getting to grips with these questions is a good place to start, the answers to which may prompt a series of potential mitigation measures.

Facility hardening, enhanced preparedness and response planning, and organizational measures to limit the impact of any single extreme event are among the risk mitigating steps companies can take, along with acquiring insurance policies.

Another option is to leverage the engineering and risk management expertise of third parties.

Independent risk assessments and audits can serve as vital tools in quantifying actual risks, with engineering-based studies revolved around rigorous site-specific technical assessments enabling facilities to measure their exposure to numerous natural hazards. This can carry advantages over advice and subsequent cover offered by insurance firms, which may not offer this level of rigorous evaluation and technical understanding.

Regardless of what approach is taken, companies must build risk into their cost of business and plan for a certain degree of extreme weather disruption every year.

A step-by-step approach

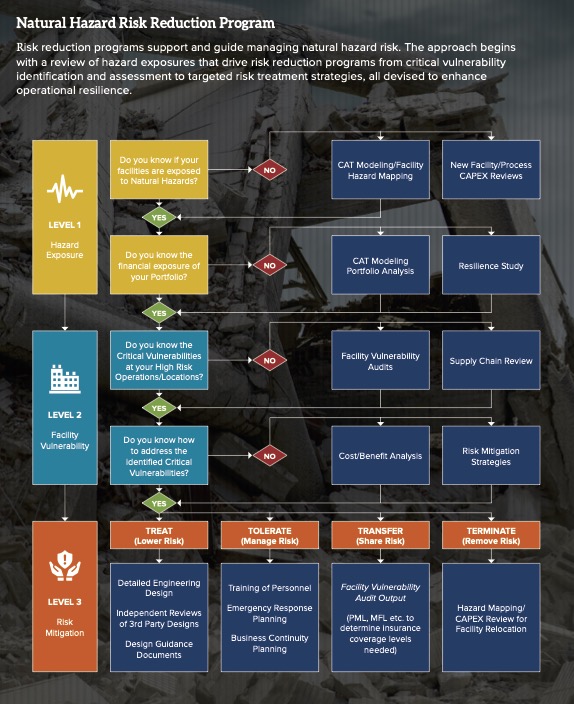

Risk reduction programs support and guide how to manage natural hazard risks. As the illustration shows, the approach begins with a review of hazard exposures that drive risk reduction programs from critical vulnerability identification and assessment, to targeted risk treatment strategies – all devised to enhance operational resilience.

- Step 1: Hazard exposure

Do you know if your facilities are exposed to Natural Hazards?

Do you know the financial exposure of your portfolio? - Step 2: Facility vulnerability

Do you know the critical vulnerabilities at your high-risk operations and locations?

Do you know how to address the identified critical vulnerabilities? - Step 3: Risk mitigation

From detailed engineering design through to independent reviews of third-party designs, the training of personnel, emergency response planning and business continuity plans, there are various approaches to treat, tolerate and transfer risk.

Terminating and removing the risk needs hazard mapping and CAPEX reviews for facility relocations for example.

Future proofing through knowledge sharing

Some organizations may lack the in-house technical and engineering expertise to properly plan and execute an entire natural hazard risk management strategy.

Expertise in the field of process safety (including accidental hazards such as fires, explosions and toxic spillages) and structural engineering is critical for companies to get the support from the cradle-to-grave process.

Specific services, such as risk assessments and independent audits; equipment elevation audits (flood risk); natural hazard audits (from backup power systems to data protection); flood and storm surge risk analyses; reviews of emergency response plans; and much more – such as a Natural Hazard Risk Management Toolkits which offer insights and resources to assist industrial facilities in reducing their exposure to natural and man-made hazards.

Knowledge sharing is crucial if organizations with assets prone to natural hazard risk are to futureproof themselves effectively.

In the UK, for example, there are a number of conference papers planned for the Hazards31 conference, a virtual event taking place in November that focuses on issues around process safety.

Here, flooding is the most frequent and damaging natural hazard, the risk of which is growing due to climate change and increasing regularity of extreme weather events. To help organizations understand and prepare for these risks, these types of conference papers look at vital lessons learned through the years, and how to navigate the UK’s Control of Major Accident Hazards (COMAH) regulations.

With more industrial businesses in the UK, wider Europe and other regions around the world being impacted from natural hazards there is a clear message; risk from natural hazards is growing. As climate change continues to produce extreme weather events which may become more frequent and severe, the time to act is now.

Energy Connects includes information by a variety of sources, such as contributing experts, external journalists and comments from attendees of our events, which may contain personal opinion of others. All opinions expressed are solely the views of the author(s) and do not necessarily reflect the opinions of Energy Connects, dmg events, its parent company DMGT or any affiliates of the same.

KEEPING THE ENERGY INDUSTRY CONNECTED

Subscribe to our newsletter and get the best of Energy Connects directly to your inbox each week.

By subscribing, you agree to the processing of your personal data by dmg events as described in the Privacy Policy.