Accurate measurement and traceable calibration for clean fuels

As we move towards a cleaner and greener future, clean fuels such as hydrogen and methods of reducing carbon dioxide emissions such as Carbon Capture, Utilisation and Storage (CCUS) schemes are becoming increasingly important. However, with these new developments comes a set of measurement challenges that need to be addressed in order to maintain the reliability and accuracy of metering systems. Traceable calibration is a challenge that needs to be considered, and it can be particularly important in the case of clean fuels.

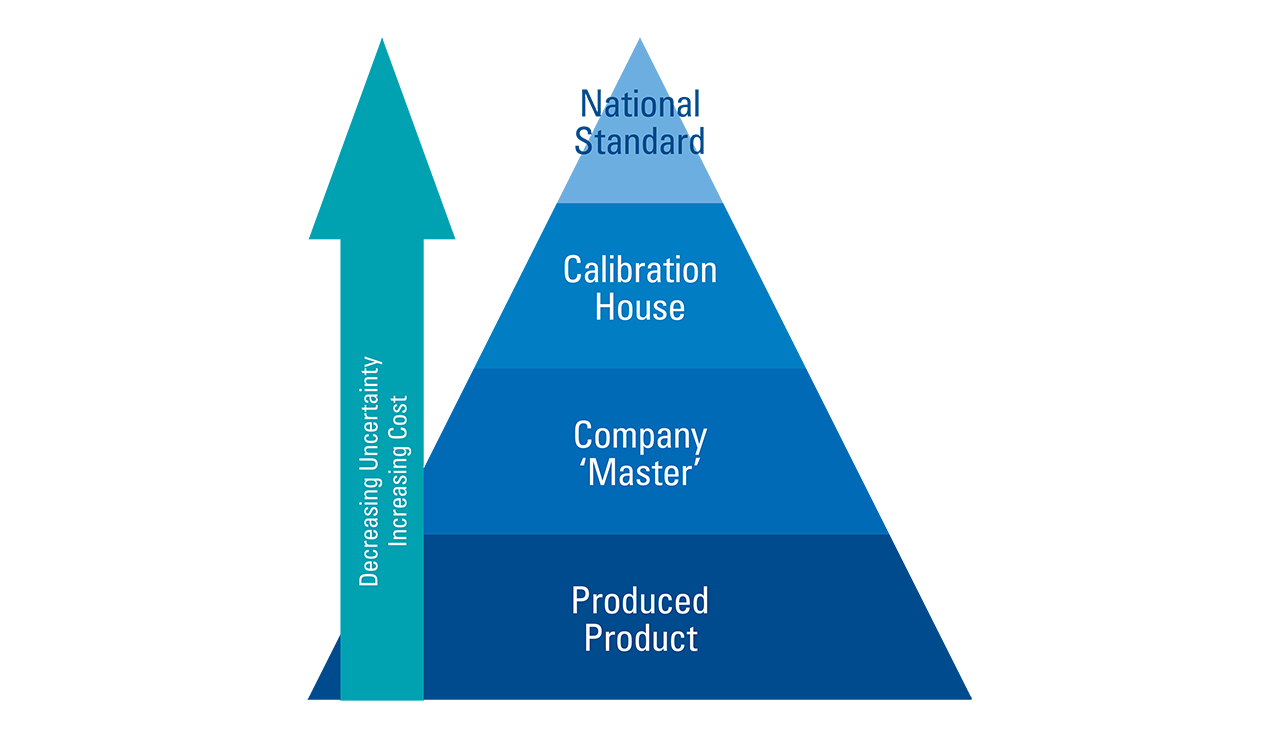

Traceability involves being able to trace measurements to a National Standard, ensuring that the measurements are accurate and reliable. This is typically pictured as a ‘chain’ or ‘pyramid’ of traceability (Figure 1), where the accuracy improves as you rise up the pyramid stages until the national standard is reached. Without traceability, there is no impartial verification of measurement accuracy, resulting in penalties such as poor meter performance, and reduced customer and stakeholder confidence. Customer confidence is vital for securing a fair clean fuel economy. Maintaining traceability can create trust in measurement accuracy and reliability of meters. Nevertheless, there are several challenges in the way of achieving this goal, especially for measurements related to hydrogen and CCUS.

Figure 1: The traceability pyramid

CCUS challenges

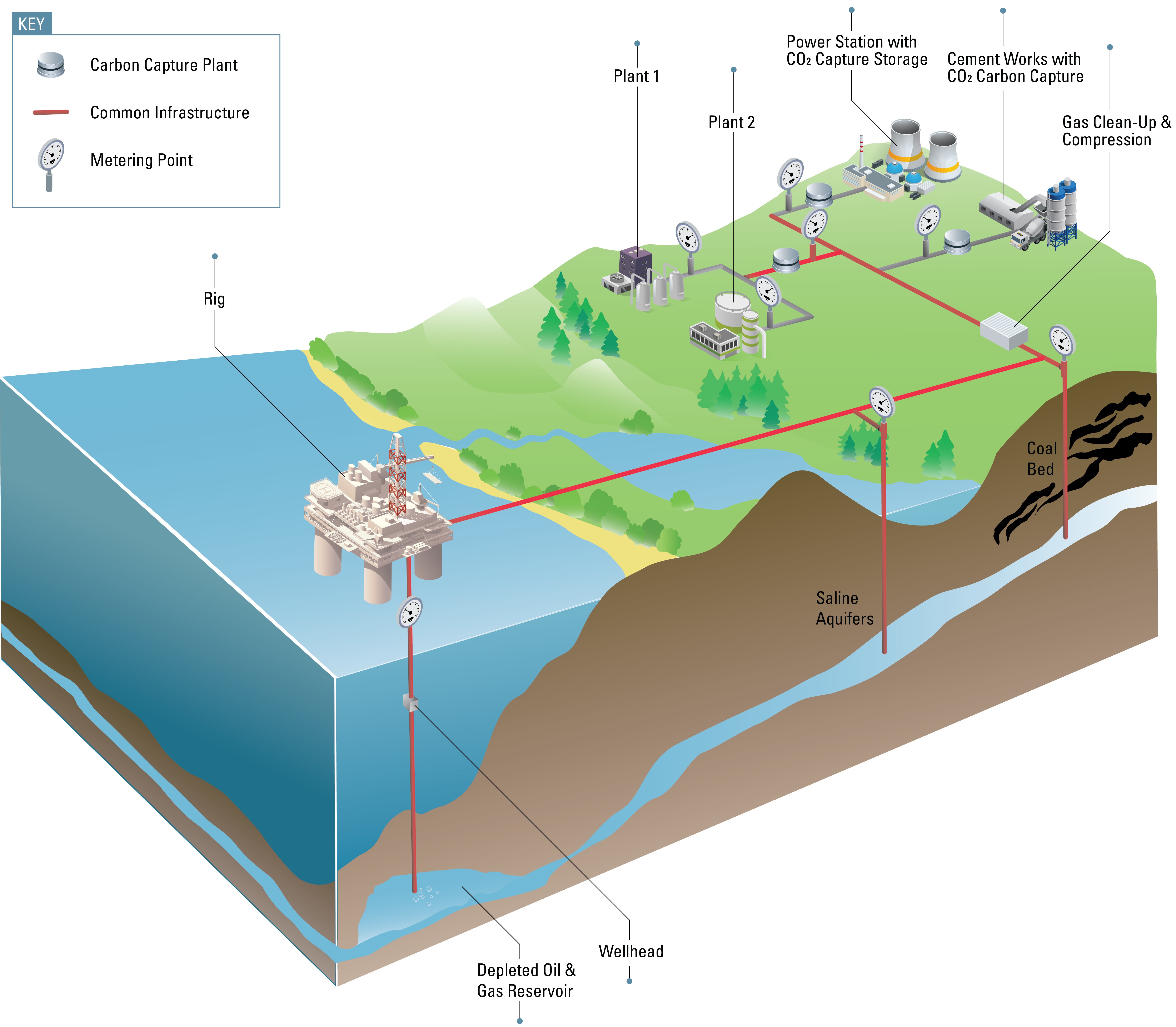

CCUS is considered one of the key tools for reducing the emission of carbon dioxide (CO2) into the atmosphere. However, there are issues around accurately measuring the flow rate of CO2 in the CCUS process, both in the gas and dense phases, that should be considered. The accuracy of CO2 measurements is important because CCUS schemes are expected to be monetised. If there are regulations on the maximum amount of CO2 emitted or a price for its annual sequestering rate, then we need to be able to accurately quantify this. The higher the ‘price’ of CO2, the greater the incentive for accurate quantity (and purity) measurements since a greater measurement uncertainty corresponds to a greater financial exposure.

Figure 2: CCUS process

Compared to other fluids, the Triple Point and Critical Point of CO2 are relatively close to the ambient temperature and typical pipeline operating pressures. This means that in some cases the operation/transportation conditions are not far from the gas/liquid phase boundary. Therefore, variations in temperature or pressure could potentially significantly alter the fluid properties that are normally the basis of measurement techniques (density, viscosity, etc.) or even result in the phase change. Matters can get even more complicated since CCUS schemes are normally handling mixtures rather than pure CO2. The presence of impurities means that in certain temperature and pressure ranges, a two-phase gas-liquid mixture will form, and the exact temperature and pressure ranges are difficult to predict.

These are some concerns for metrology, but there are also flow assurance concerns. For example, if water is introduced as an impurity, carbonic acid can be formed and corrode certain pipeline materials. Pumps and compressors that are not designed to handle two-phase flow could potentially be less reliable to transport the CO2 at the required rates. On the other hand, boosters that are designed for use with two-phase flow tend to be far more expensive.

Hydrogen challenges

Working with hydrogen, as a promising clean fuel, can also cause different challenges. Hydrogen is smaller than other molecules and therefore tends to leak, even in systems that are leak-tight with air or natural gas. Not only it increases the likelihood for hydrogen to leak and form a flammable or explosive mixture with air, but also it can reduce the accuracy of measurement devices (such as diaphragm flow meters) due to the potential leakage of gas through their components. In addition to that, the very different properties of hydrogen compared to air or nitrogen create uncertainties about whether these gases (which are common gases in test facilities) can be used for the calibration of hydrogen flow meters.

Calibration facilities that can work with pure hydrogen are hardly available at the present time. Therefore, there is an urge for the development of these facilities or undertaking research projects that can provide assurance about the suitability of using common alternative test gases (such as air or nitrogen) for the calibration of hydrogen flow meters. The latter can be helpful in decreasing the cost of calibration and increasing the safety of the facilities considering the hazardous properties of hydrogen. Hydrogen has a wider flammability range (in terms of the mixture ratio with oxygen) and a low ignition energy (lower than natural gas). Also, pure hydrogen has an invisible flame. These factors combined mean that hydrogen poses greater risks for fires and explosions, to the point that electrical equipment such as measurement devices certified for use with natural gas is considered unsuitable for use with hydrogen in many cases. Hydrogen is normally under a separate classification under explosion prevention regulations and guidelines such as ATEX.

Hydrogen embrittlement of piping materials is also a concern for measurement devices as well as any other components in contact with hydrogen. This is where hydrogen diffuses into the surface of a material such as a steel pipe and makes it brittle and prone to failure. Hydrogen embrittlement tends to occur at high pressures, and unfortunately, many of the high-strength steels used for those pressure ranges are particularly susceptible. Conversely, materials such as copper which are normally used at lower operating pressures are very resistant to hydrogen embrittlement.

Another primary challenge of traceable calibration for clean fuels is the availability of reference standards. A reference standard is a measurement device that is used as a benchmark for comparing the readings of other measurement devices in their calibration process. These standards must be traceable to recognised national and international metrology institutes. At the present time, the availability of reference standards for clean fuels are limited. To address this challenge, it is essential to develop new reference standards for clean fuels and ensure that they are easily and widely available to fuel producers and distributors. TÜV SÜD National Engineering Laboratory has a vast experience of developing and maintaining flow measurement standards, and we have been involved in the research and development of standards for clean fuels, and the intercomparison of reference flow measurement devices. As an example, the only UK’s primary field standard for testing dispensers at Hydrogen Refuelling Stations (HRS) has recently been developed by TÜV SÜD.

Figure 3: The availability of reference standards for clean fuels are limited

A field standard is necessary because flow measurement errors can stem from sources beyond the meter itself. In an HRS, for instance, the design of the dispensing system and the process of refuelling can cause measurement errors. At the end of every refilling by a customer, the dispenser hose downstream of the meter should be vented for safety reasons. Furthermore, some pressurised hydrogen is normally left in the dead volume between the hose and the meter. Therefore, the aforementioned amounts of hydrogen are measured by the flow meter but not being delivered to the customer. Although correction methods can be used to compensate for these, the total measurement error of the entire system rather than just the meter alone must be determined in such cases where there are extra factors contributing to the measurement errors. This is why a field standard is required to make sure the billing based on the measurements is fair.

To achieve a clean fuel economy there are numerous other challenges that must also be addressed to ensure that accurate measurements are obtained, and clean fuels are successfully integrated into the energy mix. Some of the challenges that exist are uncertainty about the suitable technology, lack of standards, guidelines, and regulations, the complexity of the composition of new fuels and their compatibility with the existing infrastructure, and the cost of transition. It is crucial to address and overcome these challenges to create a sustainable future that relies on clean fuels. At TÜV SÜD, we are committed to playing a significant role in achieving this objective.

KEEPING THE ENERGY INDUSTRY CONNECTED

Subscribe to our newsletter and get the best of Energy Connects directly to your inbox each week.

By subscribing, you agree to the processing of your personal data by dmg events as described in the Privacy Policy.