Michelin Is Out to Make the World’s Greenest Tire

(Bloomberg) -- Making tires for an electric vehicle is a ruthless exercise in compromise. Too much stick and the car won’t travel as far on a charge; too little, it will silently slide off the road. Exacerbating the equation is the fact that these vehicles are ponderously heavy.

Michelin, however, says it has finally perfected the mix after 30 years of tinkering with its rubber recipes. If EV ranges tick slightly higher in the next few months, the battery chemists won’t deserve all the praise; save some for the tire wizards.

Next: they want to make that same tire a data engine and, while they’re at it, fully recyclable.

Hyperdrive caught up with Alexis Garcin, chairman and president of Michelin North America, to talk about the company’s R&D blitz and how he’s preparing for a massive wave of electric vehicles.

How does your approach change with an electric vehicle?

It has more or less the same complexity as making a tire for a combustion car, but it brings it to another level. You have to ensure safety but you have to minimize resistance, because it has a direct link with the fuel consumption. And the high tech materials used have to be lighter and lighter, because if the car is getting heavier, we have to make sure that the tire won’t. That’s really a subtle mix.

So these tires are purpose-built for EVs?

In March, we unveiled the e.PRIMACY, which will come later this year for larger SUVs in the U.S. That tire is bringing up to 7% additional range to electric vehicles, because it is optimized to reduce the road resistance without compromising any of the performance. That’s a technology we mastered and we’re just rolling it out.

The second example is on the Pilot Sport, which we just released. It’s a dedicated tire for electric sports cars and it brings up to 37 miles of additional range, because of that optimization of running resistance.

What does R&D look like now?

We have massively re-accelerated our investments in what we call the high-tech material division. Those open us up to new domains, like aerospace, like medical and other industries. Our vision is to have a fully renewable and recyclable tire by 2050. Today, more or less, 30% of the tire is renewable and recyclable.

Is the size of vehicles today a challenge?

We have to adapt constantly our production system to that. Ten years ago, I would say we were massively producing 16- to 17-, maybe 18-inch products; today we are definitely in the 20, 22-inch range and already increasing production on 24-inch tires.Has EV adoption changed your sales and distribution strategy?

I think personally what’s happening right now is a deep transformation of the auto industry and it pushes the car manufacturers to think about a new business model. The value stream will probably move from buying a car and getting maintenance to some services that you buy every month or some packages you can integrate every 6 months, depending on new features and technologies that are being developed. We were the first manufacturer, starting in 2012, to put an RFID chip in every medium- and heavy-duty truck tire. By 2023, every passenger car tire will be equipped with an RFID chip because we believe they are a nice business model. There are so many offers we can build around tires, because at the end of the day that’s the only part of the car touching the road.

Can you give me some examples?

I see the RFID as an enabler. It’s not there to store information; it’s just like your social security number. Once it’s in the cloud, every time that tire shows up for maintenance, you can track that mileage and then you can push some information to the driver: ‘By the way, it might be time for you to make a rotation,’ or ‘you should be very close to the minimum tread depth and you might think about changing your tires.’ This is the kind of information that we can very easily share and deploy today. It’s even more valuable for the B2B customers. When you have a 10,000-vehicle fleet, this is a gold mine, because it’s such a high source of efficiency.

Are you talking to automakers earlier in the process?

I would say so. They need a strong partner to cope with the challenges they face when they are designing the vehicle — the range and the weight and the noise and everything we just talked about. And each one of them might have a different approach in terms of their after-market strategies. The after-market — [warranties, long-term service, extra parts ]— will be completely revamped in the next five or 10 years.

When you have these conversations, with say, Tesla or Rivian, how customized do you get?

When we talk to [manufacturers], most of the time, the tires developed are made specifically to those cars. Because the cars are so unique, because of the interaction of the weight, the torque and the chassis of the vehicle, each one is different. Most of the tires are very, very tuned and made specific down to the model level. It’s much more complex than it appears.

More stories like this are available on bloomberg.com

©2021 Bloomberg L.P.

KEEPING THE ENERGY INDUSTRY CONNECTED

Subscribe to our newsletter and get the best of Energy Connects directly to your inbox each week.

By subscribing, you agree to the processing of your personal data by dmg events as described in the Privacy Policy.

More renewables news

GE Vernova Expects More Trouble for Struggling Offshore Wind Industry

GE Vernova to Power City-Sized Data Centers With Gas as AI Demand Soars

Longi Delays Solar Module Plant in China as Sector Struggles

Australia Picks BP, Neoen Projects in Biggest Renewables Tender

SSE Plans £22 Billion Investment to Bolster Scotland’s Grid

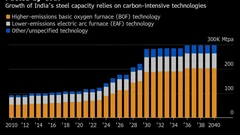

A Booming and Coal-Heavy Steel Sector Risks India’s Green Goals

bp and JERA join forces to create global offshore wind joint venture

Blackstone’s Data-Center Ambitions School a City on AI Power Strains

Chevron Is Cutting Low-Carbon Spending by 25% Amid Belt Tightening